Fab-Labs and Makerspaces as Digital University Infrastructure – Potentials of Open Workshops for an Open University

Fab-Labs and Makerspaces as Digital University Infrastructure – Potentials of Open Workshops for an Open University

29.10.19

“Digital prototyping and experimentation with hardware offers many potentials for universities: (interdisciplinary) research, (applied) teaching, student projects offer space for further development, cooperation and exchange with civil society and companies as well as cooperation with schools and public institutions that cannot operate such an infrastructure”. In her guest article, Melanie Stilz, from the BMBF-funded research project Fab101, writes about Fab labs at universities.

This article was automatically translated using DeepL Translator. Please excuse any errors.

![Fab-Lab & Maker-Space. Photo: [https://unsplash.com/photos/TgQQPY6BfGI Jack Young] Fab-Lab & Maker-Space.](/sites/default/files/images/blog/jack-young-TgQQPY6BfGI-unsplash2.jpg)

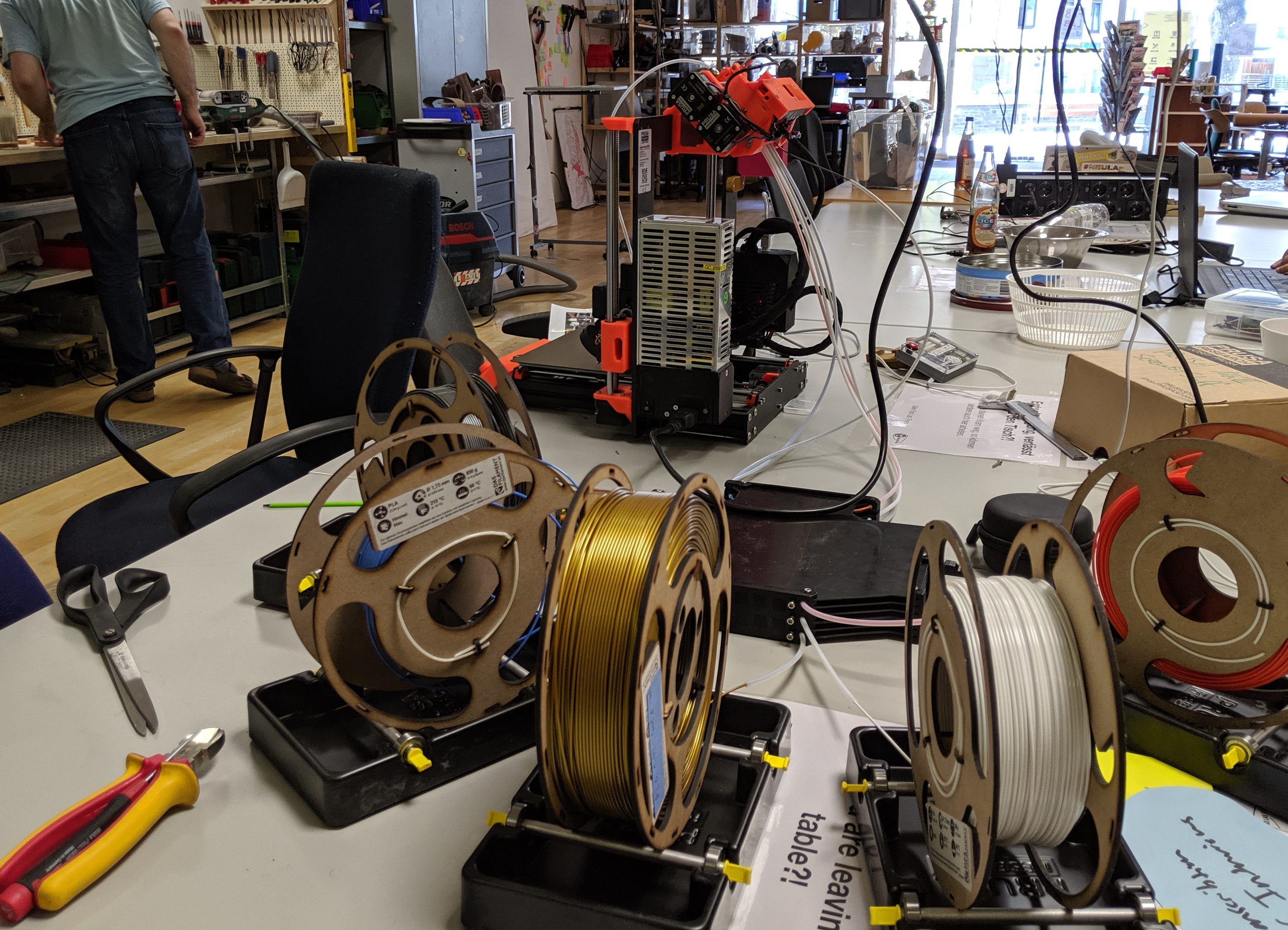

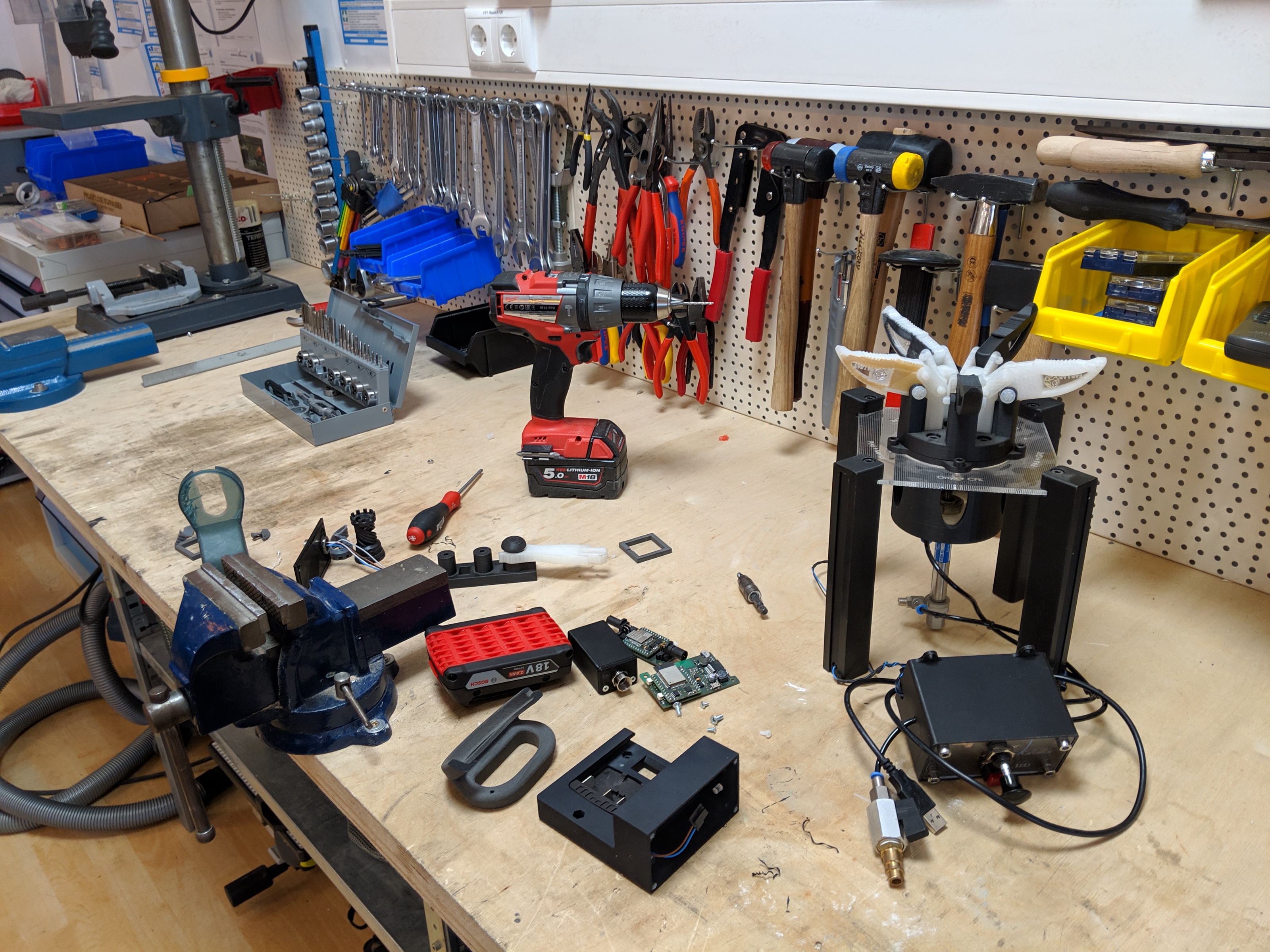

Rapid prototyping (or: model making with digitally controlled machines) has found its way out of production technology into hobby cellars and craft workshops under the keyword “making” for several years now. With the help of digital manufacturing machines such as 3D printers or laser cutters and thanks to ever cheaper microelectronics and single-board computers, the development of digital prototypes no longer requires an infrastructure costing millions. The open workshops, which provide the necessary equipment and personal expertise in the form of their members, are called fab labs, repair cafés, hacker or maker space. Depending on the definition of exactly what constitutes a “fab lab”, there are between 1700 and several thousand such places worldwide. Maker Media, among other things operator of the “Maker Faires” in the German-speaking area, registers for Germany about 250 Makerspaces, including many public institutions like libraries, schools and universities.

Under the mentioned terms, only Fab-Labs is more precisely defined for what they are and do. Although there is no formal legal examination as to whether the title Fab-Lab may be used or not, visitors, other Fab-Labs and the worldwide coordinating Fab Foundation expect that the Fab Charter : ´Diese makes some demands on the Fab-Lab and its users, which we also recommend as an orientation for the operation of a university Fab Lab or maker spaces. For the sake of simplicity and because of its proximity to science, the term “Fab-Lab” will therefore be used in the following as an umbrella term, even if it does not only refer to registered Fab-Labs.

The first Fab-Lab at a university

At the turn of the millennium, Prof. Dr. Neil Gershenfeld of the Massachusetts Institute of Technology (MIT) decided to offer a highly experimental course that he called How to Make Almost Anything (HTMAA). In terms of content, he was concerned with the examination of innovative manufacturing technologies, which ranged from computer-controlled production machines (CNC) and (micro)electronics to more traditional, manual processes. Gershenfeld had originally planned a small, project-driven course for particularly interested students, but it met with a great response from all faculties. The course was not only several times overbooked, it also took on a depth and breadth of content in the following years that Gershenfeld had not expected. Since then, HTMAA has not only been offered continuously, but has also formed the nucleus of numerous other activities, including the conception and founding of the first fabrication laboratory, in short Fab-Lab at MIT 2001.

.

The first German university with its own Fab Lab was the RWTH Aachen University in 2009, in the following years more were constantly added. From student-run labs in basement rooms, which live from voluntary commitment and donations, to central facilities with fixed courses and staff, everything is now available. Currently, depending on the interpretation of the term (many of the places known as Fab-Labs are only accessible to a limited group of users, which does not correspond to our definition), 20 – 30 German universities with their own Fab-Labs are known to us. Many more are in the planning stage, for example funded by the BMBF StartUpLab@FH funding measure, which will be launched this autumn.

Fab labs at German universities

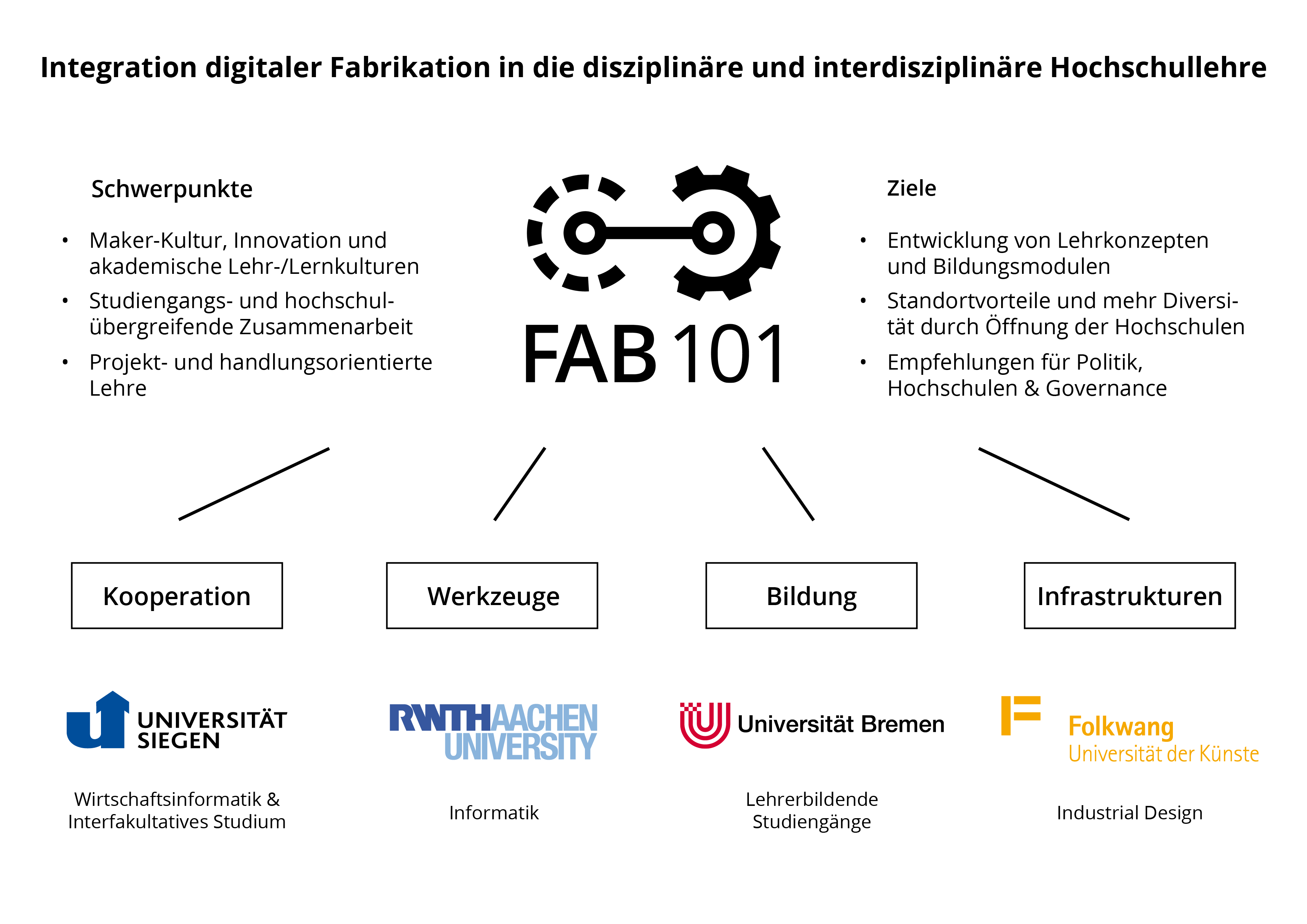

In the research project Fab101[7] funded by the BMBF, the University of Siegen, the RWTH Aachen, the University of Bremen and the Folkwang University of the Arts have been dealing with Fab labs at universities since 2017.

For universities, digital prototyping and experimentation with hardware offers many potentials: (interdisciplinary) research, (applied) teaching, student projects offer space for further development, cooperation and exchange with civil society and companies as well as cooperation with schools and public institutions that cannot operate such an infrastructure. The diversity of these application scenarios is also reflected in the German university labs, which were contacted and surveyed in the context of this research. The knowledge gained primarily answers two questions (we answer these and other questions in detail in our “Fab-Lab Handbook” published in 2020):

- If this is such a great thing – why doesn’t every university have a Fab-Lab? And afterwards:

- Ok, maybe it’s complicated – why is it still worthwhile for universities to think about a Fab-Lab as infrastructure?

Fab-Labs: What do I want?

A university lab lab has certain expectations; it provides more than just a technical infrastructure. It is not 3D printers, laser cutters and CNC milling machines that make up a Fab Lab, but rather the basic concern of learning together, openness and accessibility, as well as the willingness to cooperate and share knowledge. Classical laboratories, workshops or training workshops, such as those found at most universities, often have extensive machinery at their disposal, but have a different task than fab labs. They serve either to support research and teaching by skilled personnel, or to train a selected target group, for example within the framework of a course. Free project work and access for outsiders, as is usual in a Fab lab, is not usually provided for.

The basic prerequisite for the operation of a Fab Lab is the availability of premises that provide the necessary ventilation, dust and noise protection and are easily accessible at the same time. If there is no budget for extensive construction work, it can be worthwhile to find out which premises are unattractive for other players – but perhaps ideal for a fab lab. An extended storage room, an unused warehouse or remote basement rooms can, with a little creativity and sufficient LEDs, become the social centre of a university. A sensible coffee maker and a refrigerator with mate supplies reinforce the effect. As an alternative, it can also be worthwhile, as in the example of Siegen, to enquire about empty city buildings in or near the city centre and relocate the Fab-Lab outside the campus – as long as this does not make the use by university members too cumbersome.

For the operation of a university lab lab one should therefore see the advantages in the openness towards an ordinary workshop and be prepared to pay the associated additional costs. As a reward, projects, potentials and synergies can develop for which a closed framework offers no room for development. The already mentioned course “How To Make Almost Anything” for example was first opened for other faculties, a few years later it formed together with the first Fab-Lab at the MIT the basis of the Fab Academy, a global network of Fab-Labs at universities which offer with the Fab Diploma the meanwhile most important certificate for Maker.

Who makes a Fab-Lab?

The impulse to enable and operate such an open place and then to implement this project arises in most cases from the commitment of individuals or small groups: a chair, committed employees, a group of students. For the implementation of the project, we are looking for comrades-in-arms, financing possibilities and premises. With a little luck and a high commitment of all participants, we find a solution that is in a constant flow with regard to personnel, financing and institutional integration. The position of a fab lab between teaching, research, service and leisure rarely offers long-term security, but a high degree of independence, which can also be advantageous in an otherwise not always dynamic university structure. Although the regularly changing staff must always be re-integrated, it also brings new perspectives and a high level of motivation. With the growing number of fab labs in the German higher education landscape, however, the need to find sustainable solutions and to enable stronger institutional embedding is also growing. Fab Lans that are affiliated to libraries, business incubators or other central institutions are still the exception.

University Fab Labs: Who’s allowed to do what?

The advantage of a Fab lab attached to a central institute is an often already established access control system, such as library cards or other chip card systems, as well as visibility and barrier-free access. There are reliable opening hours and services, and ideally there are at least some staff available who do not change with the cycles of third-party funding projects and need to be re-integrated. In order to maintain such a central position, however, sufficient time and political persuasion are needed at the university.

Independent of this, Fab-Labs are generally available to university staff and students and can also be used exclusively for research or teaching purposes. For harmonious co-production, some have developed their own booking systems for access, machine use and supervision. The commitment of students almost always plays an important role for the company, a fab lab does not offer services in the classical sense but lives from the (student) community. They often also define offers and opening hours. The involvement of students as tutors, through study projects or theses can be decisive for them to identify more strongly with the Fab lab and to get involved in the lab on their own initiative, even in their free time.

For the involvement of the public the most common solution is the “Open Lab Day”. A fixed day on which the use of the Fab Lab is open to everyone under supervision. Through individual cooperation, most Fab labs also have numerous other interfaces for cooperation with external parties, in particular with companies, educational institutions and civil society organisations.

What does a Fab-Lab at a university cost?

Many Institute Fab Labs emerge from favourable opportunities: a research project leaves a CNC milling machine behind, there is residual funding for a 3D printer, a laser cutter on permanent loan, and a room has just become available in the basement – and with a little luck, there are still appeal fees and available. Such a constellation is often the starting point or the first impulse for a Fab-Lab, which depends on small financial means but a lot of personal commitment. If the latter is the case, the university will be responsible for the basic willingness to support such a place, as well as for the premises and operating costs. As already mentioned, student participation plays an important role, but for regular, qualified tasks in the areas of teaching, machine care and maintenance, professional personnel should not be renounced. The question of equipment also leaves a certain scope for improvisation, which can, however, impair the quality and reliability of the offer. If the initial situation is not “no money”, the recommendations of the Fab Foundation, which estimate a budget of approx. 100,000€ for the basic equipment of machines and materials for a Fab lab, can provide orientation when it comes to design and equipment. In the concrete case, however, the requirements are rarely identical and the list should not be taken too literally. Much more important is a clear idea of which focal points should be set and which synergies are offered. So it is worthwhile to inform other faculties about the plans at an early stage, because it is not uncommon for equipment to stand unused in a corner after the end of a project or the departure of a colleague* and to be gratefully passed on as a loan.

Who’s gonna help me?

The points briefly outlined here, as well as many other topics relating to university Fab labs, can be read in detail in the “Fab Lab Handbook” from spring 2020, in which the results of the Fab101 research project and the annual Fab:UNIverse network meetings are dealt with. For last-minute participants, we recommend participation in Fab:UNIverse 2019, which is also the final conference of Fab101 and will take place on 6 November 2019 at the Einstein Center Digital Futures, Berlin. This year we are looking forward to presenting exciting inputs and workshops as well as “The Fab-Lab Handbook”. Further information on the handbook, on upcoming Fab:UNIverse network meetings and on this year’s final conference can be found at https://fab101.de/.

Theresa Sommer

Theresa Sommer

Inga Gostmann

Inga Gostmann

Dr. Björn Fisseler

Dr. Björn Fisseler